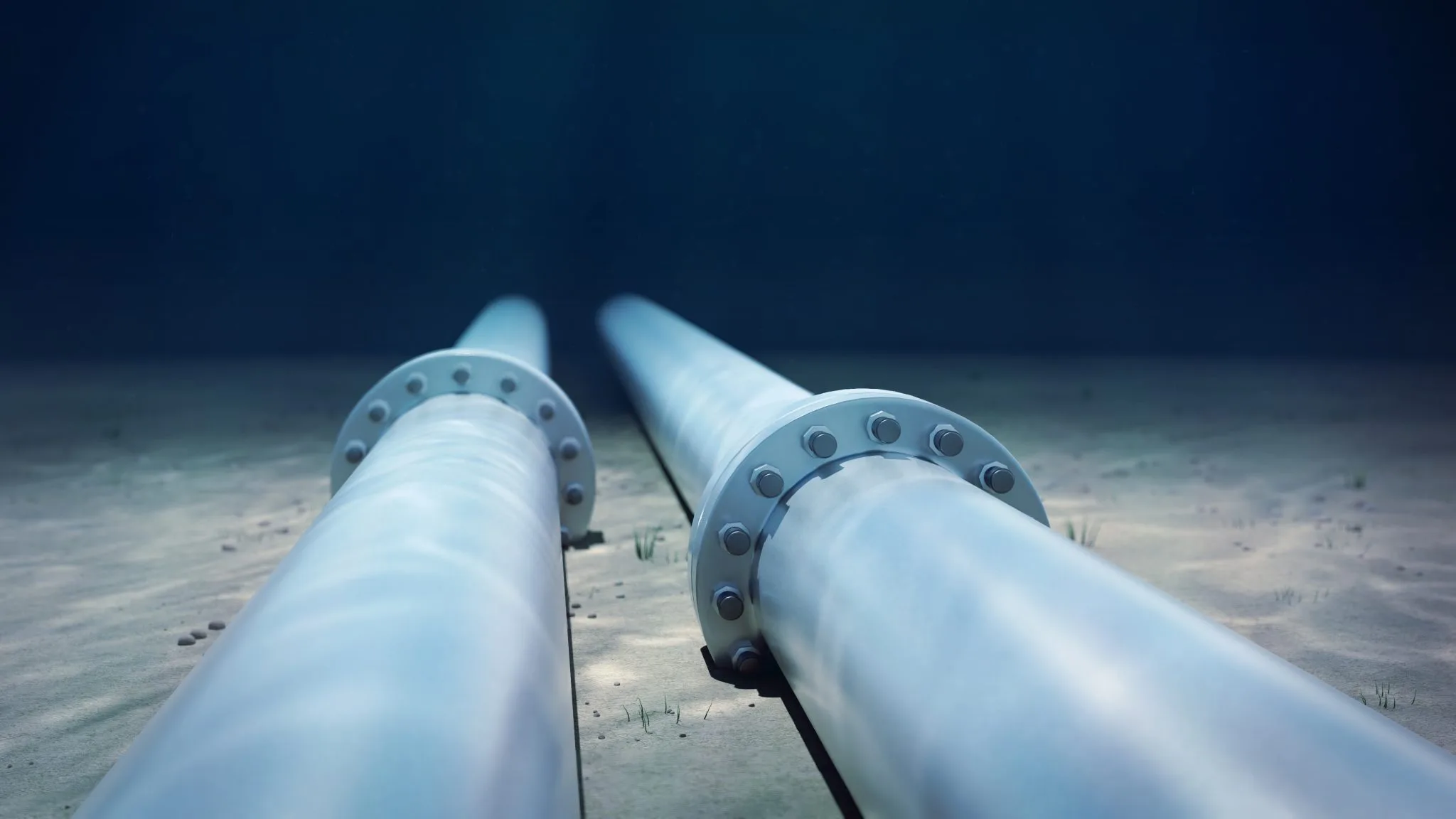

Subsea pipelines are designed and constructed to transport oil or gas from the depths of the ocean to shore for our consumption. Pipelines typically span from the wells to either a FPU (floating point unit) or FPSO (floating, production, storage and offloading) vessel. The section of pipeline from the seabed rising vertically to either the FPU or FPSO is called a riser. It’s same as a pipeline except that its rising upward. This has its own design challenges.

Simply laying a pipeline on a seabed and attaching it to a well and connecting the other side of the pipeline to the FPU/FPSO isnt easy. The ocean isnt your friend. Waves and current pose challenges. If your design isnt solid, your pipeline might be swept away.

In order to safely design pipelines, the following aspects must be studied.

- Pipeline route selection

- Pipeline material selection

- Pipeline wall thickness calculations

- Pipe-soil interaction

- Fatigue assessment

- Hydrostatic collapse

- On-bottom stability

- Freespan assessment

- Lateral buckling assessment

- Pipeline walking assessment

- Cathodic protection

- HIPPS (Hydrostatic In-Line Pipeline Protection System)

- Pipeline protection system

- Hydraulic and Thermal Analysis

- Material Selection for External Anti-Corrosion Coating

- Material Selection for Internal Coating